Robotics is pushing into unexpected territories. In Germany, industrial robots are now being used to dismantle and recycle battery packs tackling sustainability at the hardware level. At the same time, the concept of “Physical AI” is gaining traction across manufacturing sectors in the U.S. and EU, promising smarter, more adaptive robots that go beyond pre-programmed motions. These shifts show robotics isn’t just about replacing human labor; it’s about enabling more sustainable, resilient, and intelligent industrial systems. (via Robotics & Automation News; World Economic Forum)

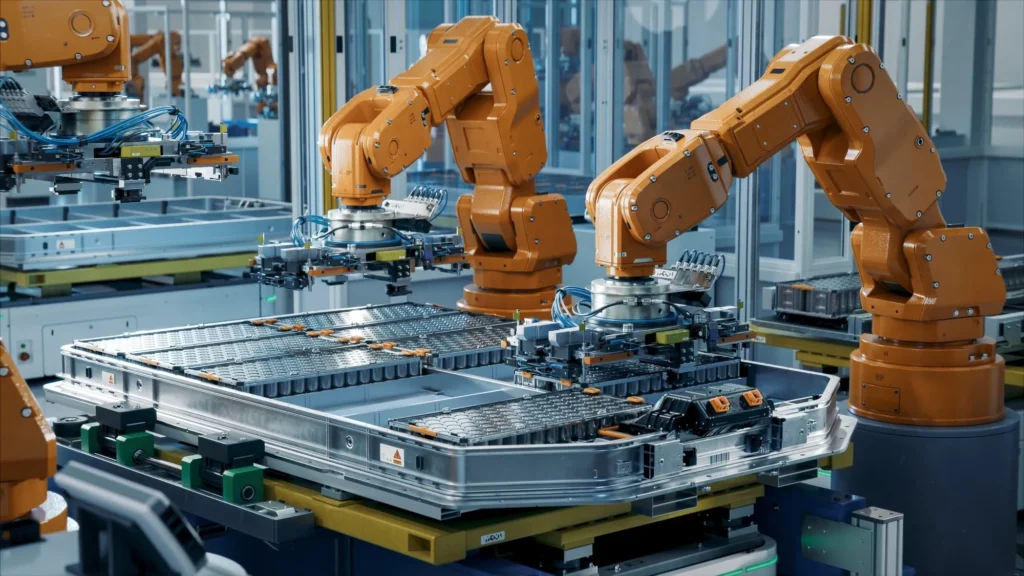

Robots & Battery Recycling: The German Case

One of the most interesting recent developments is in automated battery disassembly. Companies in Germany led by Fraunhofer IPA and robotics firms like Kuka are deploying robots in projects such as DeMoBat. These robots are tasked with dismantling used battery packs (from EVs, energy storage, etc.), handling a variety of battery designs under real‐world industrial conditions. The goals are twofold: recover materials more safely and scale recycling without relying excessively on manual labor. (Robotics & Automation News)

Physical AI: Making Industrial Automation Smarter

The term Physical AI describes a new wave of robotics that can perceive, learn, and adapt to their surroundings not just follow rigid instructions. Think of robots with vision, tactile sensors, and AI models that let them adjust when parts shift, surfaces vary, or new tasks come up. According to a recent white paper from the World Economic Forum, this is becoming critical for manufacturers facing workforce shortages, supply chain disruptions, and demands for customization. (World Economic Forum)

Market Momentum & What’s Driving Growth

The market is catching up. The robot end-effector market (that’s the part at the robot’s “hand” that interacts with objects) is projected to grow rapidly, especially as tasks become more varied and robots are required in more flexible applications. SMEs adopting cobots, automotive, packaging, electronics all of these sectors are pushing higher demand. (Insight Partners / PR Newswire)

Key Challenges Ahead

- Versatility vs Cost: Robots that can handle multiple battery pack designs or shifting manufacturing lines require more sensors, more computing, more design complexity. All of that costs money and sometimes it’s difficult to justify vs dedicated manual lines.

- Safety & Regulation: As robots handle dangerous materials or large packs, safety protocols, handling standards, and regulatory oversight become more critical. Physical AI systems introduce new failure modes (sensor drift, untrained edge cases) that need robust validation.

- Supply Chain & Maintenance: For widespread deployment, spare parts, trust in maintenance, and consistency in quality are necessary. Without strong aftersales and support, early deployments can underperform or fail prematurely.

- Training & Workforce Integration: New robotics systems often require new skills: technicians who can handle AI sensor calibration, software engineers fluent in robotics models, etc. Transitioning existing workers is a challenge especially in regions with aging industrial workforces (like much of Europe).

What to Watch Next

Here are signals that will show whether robotics is moving into this more adaptive, sustainable phase:

- Performance data from battery disassembly robots speed, error rates, safety outcomes, and how much material is recovered.

- Adoption of Physical AI frameworks in actual factories not just pilots. For example, integrating AI perception with robotics workcells that change over time.

- End-effector innovation versatile gripping, tactile feedback, modular designs. More efficiency gains will come from better hands plus smarter “brains.”

- Regulatory frameworks or standards that cover adaptive robotics safety, sensor reliability, environmental & disposal compliance.

- Investment flows venture, government grants, and manufacturing OEMs putting money behind sustainability + automation synergy (e.g. recycling, clean energy build out, etc.).

My Take

What strikes me is how robotics is branching out of its comfort zone away from just speed or repeatability, into adaptability and sustainability. Whether it’s recycling batteries to reduce waste or robots that can adapt to changing tasks rather than re-programming every time, these advances show robotics is becoming more useful in messy, real-world settings, not just assembly lines under pristine conditions. If manufacturers, regulators, and tech developers lean into these trends carefully focusing on reliability, safety, and cost this might be one of the most meaningful inflection points in robotics in years.