Canada’s agriculture sector is quietly going through a robotics revolution. Several startups, backed by government research funding, are rolling out automated greenhouses where AI-powered robots handle planting, harvesting, and monitoring. The goal? To address farm labor shortages while improving food security across the country. With climate risks rising and traditional farm workforces shrinking, Canada may be betting on robots to keep fresh food on tables.

How Robot Farming Works

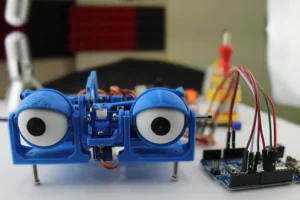

In these high-tech facilities, robotic arms and conveyor systems move plants through optimized growing conditions. Vision AI scans crops to detect pests or disease early. Automated irrigation and nutrient systems keep growth consistent, while harvest robots pick ripe produce with minimal damage. The result is a closed-loop greenhouse that runs with far fewer human workers.

Why Canada Needs It

Agriculture in Canada is facing two huge pressures: labor shortages and climate volatility. Seasonal workers are harder to secure, and unpredictable weather makes traditional outdoor farming riskier. Greenhouses solve part of the problem by controlling climate, but they’re labor-intensive. Robotics can make them scalable, producing vegetables year-round even in northern provinces.

Startups Leading the Push

Companies like Ecoation, Greenhouse Grow AI, and university spinoffs from Ontario and British Columbia are piloting robotic systems in commercial settings. Some have already partnered with supermarket chains to guarantee steady tomato and lettuce supply. Federal research grants from Agriculture and Agri-Food Canada (AAFC) have provided early funding, signalling Ottawa’s recognition that food automation is a national priority.

Benefits Beyond Labor Savings

Robotics doesn’t just replace workers it also improves efficiency. Robots can track plant health continuously, catching issues days earlier than human eyes. Data collected by sensors creates a feedback loop, letting AI models suggest adjustments for lighting, water, or nutrients. This precision lowers waste and boosts yields. For consumers, that means steadier prices and less reliance on imports.

Challenges on the Ground

Still, robot farms aren’t a silver bullet. The upfront costs of automation systems are high, often millions per facility. Farmers in rural areas may struggle to access capital or skilled technicians to maintain the machines. There’s also cultural resistance many growers are skeptical about handing food production over to machines, fearing breakdowns or over-dependence on tech suppliers.

Global Context

Canada isn’t alone in this push. The Netherlands has led the way in robotic greenhouses, while Japan and South Korea are experimenting with autonomous rice planters and harvesters. What makes Canada’s case unique is the sheer size of the country and the distance between population centers. Robotic farming could make regional food hubs more resilient, cutting transport emissions and strengthening supply chains.

What’s Next

The next few years will test whether automated greenhouses can scale. Pilot programs are already running in Ontario and Alberta, with larger facilities planned near Toronto. If successful, the government may extend subsidies or incentives for wider adoption. Private investors are also watching closely robot farms could be a growth sector for Canadian ag-tech exports.

My Take

I think Canada’s gamble on robot farms makes sense. The labor shortage is real, and climate risks aren’t going away. Robotics isn’t about replacing every farmer it’s about making farming resilient and scalable in a country where geography and weather create unique challenges. If these systems prove reliable and affordable, Canada could join the Netherlands as a model for sustainable, automated agriculture. But the industry has to tread carefully if costs stay sky-high or machines underperform, skepticism could stall momentum fast.